Manufacturing has changed a lot over the years. From manual labor to machines, the industry has evolved to make production faster and more efficient. One of the biggest advancements in modern manufacturing is CNC machining. CNC, or Computer Numerical Control, is a technology that allows machines to operate with great accuracy using computer programs.

This has transformed how products are made, reducing human errors and improving productivity. In this article, we will explore why CNC machining is so important in manufacturing today.

High Precision and Accuracy

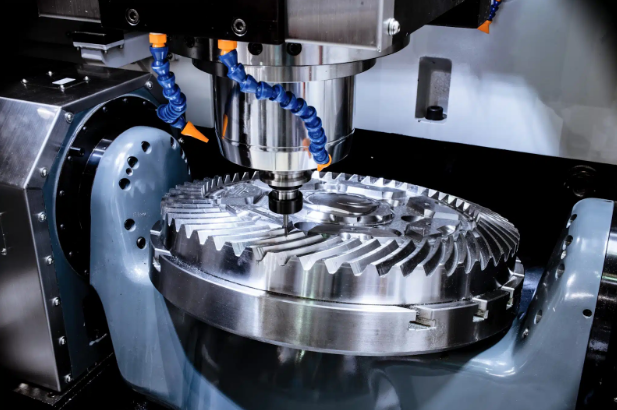

One of the main reasons CNC machining is widely used is its ability to produce highly precise parts. Unlike manual machining, where human mistakes can lead to inconsistencies, CNC machines follow exact instructions given by a computer program.

This ensures that every piece made is identical and meets tight tolerances. Industries like aerospace, medical, and automotive require extreme accuracy, and cnc machining helps achieve that level of precision.

Increased Efficiency and Speed

CNC machines work faster than traditional methods. Since they operate based on programmed instructions, they can run continuously without breaks. This helps manufacturers produce more parts in less time.

A human operator might take hours to make a single complex part, but a CNC machine can complete the task in minutes. This speed improves productivity, allowing companies to meet large orders and reduce production costs.

Reduced Human Error

Human errors can be costly in manufacturing. A small mistake in measurement or cutting can lead to material waste and defective products. CNC machines remove this problem by following pre-programmed instructions that ensure consistent results.

Once a design is created in the software, the machine replicates it without deviation. This reduces waste, lowers costs, and improves overall quality.

Flexibility and Customization

CNC machining is highly flexible. Manufacturers can create a wide range of products by simply changing the design in the software. This makes it easier to produce custom parts for different industries. Whether it’s a unique car part, a specialized tool, or a custom medical implant, CNC machines can handle complex designs that would be difficult or impossible to make manually.

Lower Production Costs

Although CNC machines require a significant initial investment, they help save money in the long run. Since they work efficiently and reduce waste, manufacturing costs go down. They also require fewer workers, which lowers labor costs.

Additionally, CNC machines can run for long hours with minimal supervision, increasing productivity without needing extra manpower.

Improved Safety

Manufacturing environments can be dangerous, especially when working with sharp tools and heavy machinery. CNC machining improves worker safety by reducing the need for direct human involvement. Since the machines are controlled by computers, operators can monitor the process from a safe distance. This reduces workplace accidents and ensures a safer working environment.

Conclusion

CNC machining has completely changed the manufacturing industry. It offers high precision, speed, efficiency, and safety, making it an essential technology in modern production. With the ability to reduce errors, lower costs, and handle complex designs, CNC machining is a valuable tool for industries worldwide.

As technology continues to advance, CNC machines will become even more powerful, helping manufacturers meet the growing demands of the future.